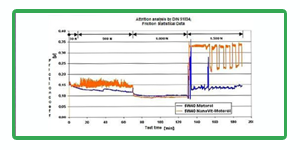

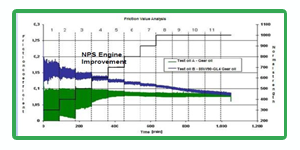

Tribological tests were performed to substantiate claims for the particle. The test used 85W90-GL4 gear oil. It was concentrated with Nano Engine Improvement at a dosage of 20mg per litre. Before the test, test pieces were put in the oil for 1hour at 50C. For comparison, there was an identical test with non-additive gear oil. The analysis with a universal tribo meter using pen and glass test pieces showed that the NPS Engine Improvement had less frictional resistance on the friction surface of the test pieces.At the test stage of 800N there was a stabilized friction resistance with a coefficient value of 0.08. For the non-additive gear oil the friction resistance decreases over the whole test period of time. This is as a result of the friction heating the oil, causing the viscosity of the oil to decrease. The wear protection of the oil is also reduced as a result. The opposite is true when using of NPS Engine Improvement. The friction coefficient at the test area of 300-600N has great, but dynamic fluctuations. The NPS Engine Improvement components sedimented on the surface compensate the test load and use the force to form a wear protection coat. The fluctuations decrease with an increase of the test load. At 800 N they are constant and independent from the test load.

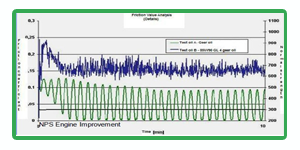

At the shown test area of 1,000 N (Fig. 8 and 9) there is a constant and dynamic effect shown in the Nano layer in comparison to the non-additive gear oil. In practice this means less wear. The balanced curve progression is due to cushioning through the elastic coat. The analysis of the key wear data demonstrates the same conclusion. The wear characteristic of the friction surface when using NPS Engine Improvement and non-additive oil is shown in Fig. 10.

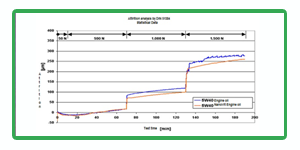

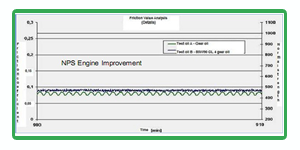

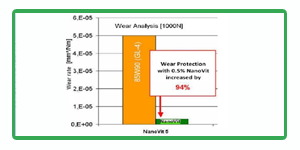

Fig. 10 : Attrition Analysis – Comparison of 85W90 and 85W90 concentrated with 5mg NPS Engine Improvement

NPS Engine Improvement has a notable effect on the attrition value. The test piece was not heated to the same extent through friction.At a test load of 700N there is less attrition. At the test load of 1,000 N the attrition is nearly zero. In comparison to the non-additive gear oil, examine the trend of the specific attrition rate. The result is that standard gear oil 85W90GL4 has a specific attrition rate of 5*10-5 mm³/Nm and Nano Engine Improvement-gear oil has an attrition rate of 3*10-6 mm³/NM. The wear analysis showed that the wear protection of 85W-90-GL4 with 0.5% of Nano Engine Improvement at an impact of 1,000 N, improved by 94 %. For the evaluation of abrasion decreasing

abilities of a product or additive it is necessary to record indicated parameter data and also to conduct a screen analysis.

The screen shows that the 85W-90 gear oil is pyrolyzed due to the high temperatures. The residues sediment on the friction surface and cause wear. The NPS Engine Improvement (20mg/litre) screen shows lowest sediments of oil plague. The friction surface is protected. The typical glow discolorations do not occur, which means an optimal friction process.

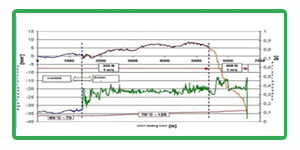

The VKA-abrasion rating analysis posed another question. How long can the NPS Engine Improvement layer support the mechanical process under complete lubrication loss? Therefore a test with insufficient lubrication on the universal tribometer with the test pieces (pen and glass) was conducted. The test oil was the half synthetic 10W40 engine oil, which was concentrated with 20mg per litre of Nano powder. Before the test the pieces were put into the test oil for a specific period of time. It started with a test load of 300 N. The analysis of the test data showed that the usage of NPS Engine Improvement extended the mechanical process and prevented deadlock by 85 minutes. Examination of the diagram below shows that under circumstances of dry running the oil film cracked and oiling was not available. If the oil film cracks in such critical areas, it threatens both the normal status and severe abrasion of the friction partners. However, at this point the Nano powder layer, which was formed under pressure and temperature, has taken over the wear protection and the lubrication function.

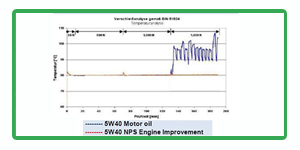

The SRV II test apparatus was used to examine the working effect of the Nano powder layer concerning friction, attrition and temperature (DIN 51834 test). The test oil was 5W40 engine oil, which was concentrated with 20mg Nano powder per litre. Before the start the test pieces (ball and disc) were put into the test oil for a short period of time. It was tested in a load between 50 and 1,500 N At 50 N the friction value of the oil in comparison to the non-additive oil 5W40 lies 0.02 higher.