a Nano particle (i.e. very small), amorphous, formless powder, which interfaces between small moving surfaces to provide protection against extreme pressure; reducing friction and decreasing wear – thereby increasing components life NPS Engine Improvement® is not a traditional additive and not based on any existing additive technology; it works by changing the dynamics of the oil film layer by forming a firmly adhesive and elastic anti-friction coating on friction stressed surfaces. In addition to the benefits of improved efficiency and improved component-life, NPS Engine Improvement® will clean the lubricant circuit and therefore the friction surfaces, improving the viscosity of the lubricant and increasing its lifetime, reducing emissions, regenerating defective spots on friction surfaces, and reducing noise and vibration.

• Self-regulating under pressure

• Flexible, elastic

• Retains lubrication abilities at high temperatures

• Steady and permanent, firmly adhering

• Very-low friction coefficient

• Improves friction values and reduces attrition

• Performance increases under pressure

• Increases period between oil changes

• Forms a firmly adhering wear protection layer

• Guarantees an elastic coating that absorbs frictional energy

• Reduction of fuel consumption

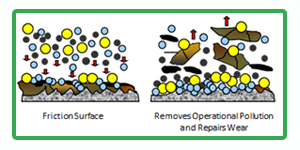

NPS Engine Improvement is NOT an oil additive. NPS Engine Improvement is a special mixture of aluminum dioxide, modified silicon dioxide and plasma processed graphite. It uses the oil in your vehicle as a deliver system to get to the friction zones of your engine. In its nano amorphous form, the aluminum dioxide functions first as a cleanser, removing the operational contaminates that build up on an engine over time, reducing its effectiveness.

It then bonds with the metal, filling in the damage that occurs in an engine due to normal operations and return it to it original geometry. The silicon dioxide and graphite create a two dimensional sliding layer that dramatically reduces any additional damage to the friction parts of the regenerates the oil.

NPS Engine Improvement is self regulating under pressure and retains its lubrication properties at high temperatures of up to 1200°C. That combination increases the oil viscosity even at significantly higher temperatures providing better engine protection. The benefit of nanotechnology is by using extremely small, engineered particles, reach traditionally inaccessible surfaces and provide and coat them..

NPS Engine Improvement is simple to use and stays in the engine even after multiple oil changes.

Demonstrated Performance NPS Engine Improvement has been extensively tested both in the laboratory and on the road. TÜV Thurgingia, Europe’s leading certification firm, performed rigorous tests and verified that a single application of NPS Engine Improvement cleanses the engine of slurry, lacquers and resins, creates a long lasting resistance wear, optimizes engine performance and reduces harmful emissions. Long-term field testing has confirmed the increase in fuel efficiency and the decreased in emissions and frequency of oil changes.

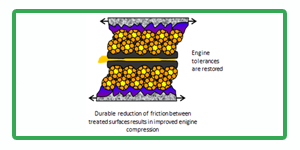

An elastic, ball-shaped molecular net structure is formed on the active centers of the friction areas within composite engines or mechanical working processes through NPS Engine Improvement Product Technology. That means the existent pressure and temperature of the aggregate is used to form and to support the self-regulating structure. This results in: - A decrease of the friction coefficient - An improvement of the load rating of the lubricants - An improvement of the work efficiency of the aggregate The uniqueness of NPS Engine Improvement: It is a combination of coat systems and high-performance lubricants. This system is seen as unique, because at the present time coat systems and high-performance lubricants are being seen separated. At the moment the existing coat systems are, e.g. ceramic coats or MoS2 sliding lacquer, which are creating an adherence coat on the friction surface and are possible to change it. NPS Engine Improvement itself adjusts individual to the collective like a “dynamic sponge”. The formed oil bearing chains help to improve the output.